In today's world of consumer electronics, where there is a continuous pursuit of thinner, lighter devices with longer battery life, the energy efficiency of backlight systems has become a critical bottleneck. Traditional solutions often suffer from low efficiency in light-load scenarios and inadequate thermal performance, severely limiting device battery life and introducing reliability risks.

The leading mixed-signal company, AWINIC, has launched a new-generation boost-type LED driver chip—the AW9967FSR. Leveraging scientifically advanced thermal management technology, it delivers exceptional heat dissipation capabilities, boasting an ultra-high efficiency of 89% and an ultra-low thermal resistance of 110°C/W. This chip safeguards the provision of products with higher efficiency and superior quality, redefining the performance ceiling for compact driver chips!

01 Key Product Features

Input voltage range: 2.7V ~ 5.5V

Utilizes FC-SOT packaging with better heat dissipation, achieving package thermal resistance as low as 110°C/W

Supports 0.3% PWM dimming

Integrated 40V / 2.7A N-MOSFET

Reference voltage: 200mV

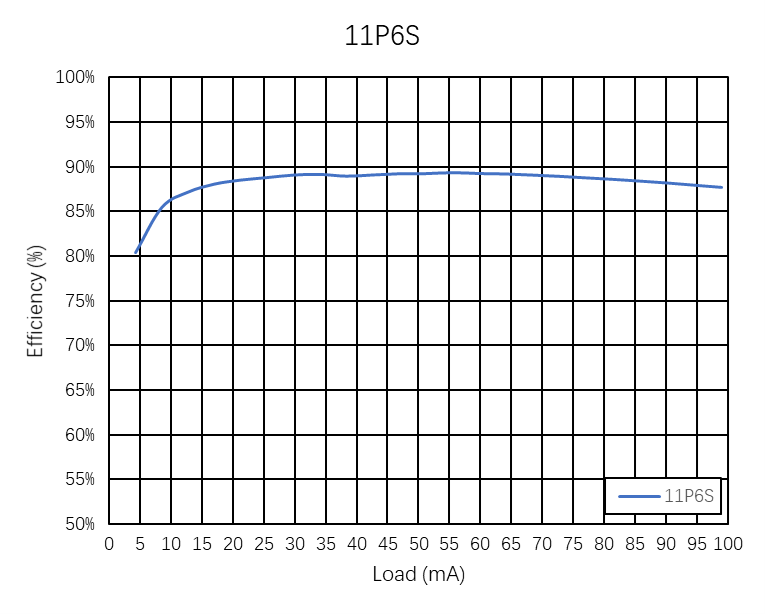

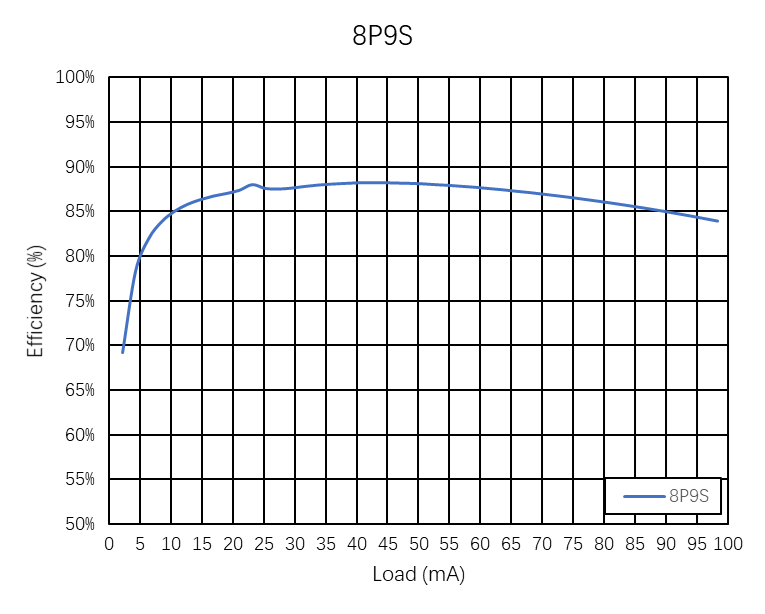

Efficiency up to 89% in a 2p7s configuration

Supports CABC (Content Adaptive Brightness Control)

Operating frequency: 1.1MHz

38V output over-voltage protection

Integrated over-current and over-temperature protection

Built-in soft-start function

02 Application Scenarios

Single-cell Battery Driving Large Screen Backlight

The AW9967FSR is suitable for tablets 12 inches and below. For designs with fewer than 50 LEDs, it supports direct power supply from a single lithium battery. For applications requiring more than 50 LEDs, a boost chip can be used to raise the inductor supply voltage above 5V, thereby achieving higher backlight brightness.

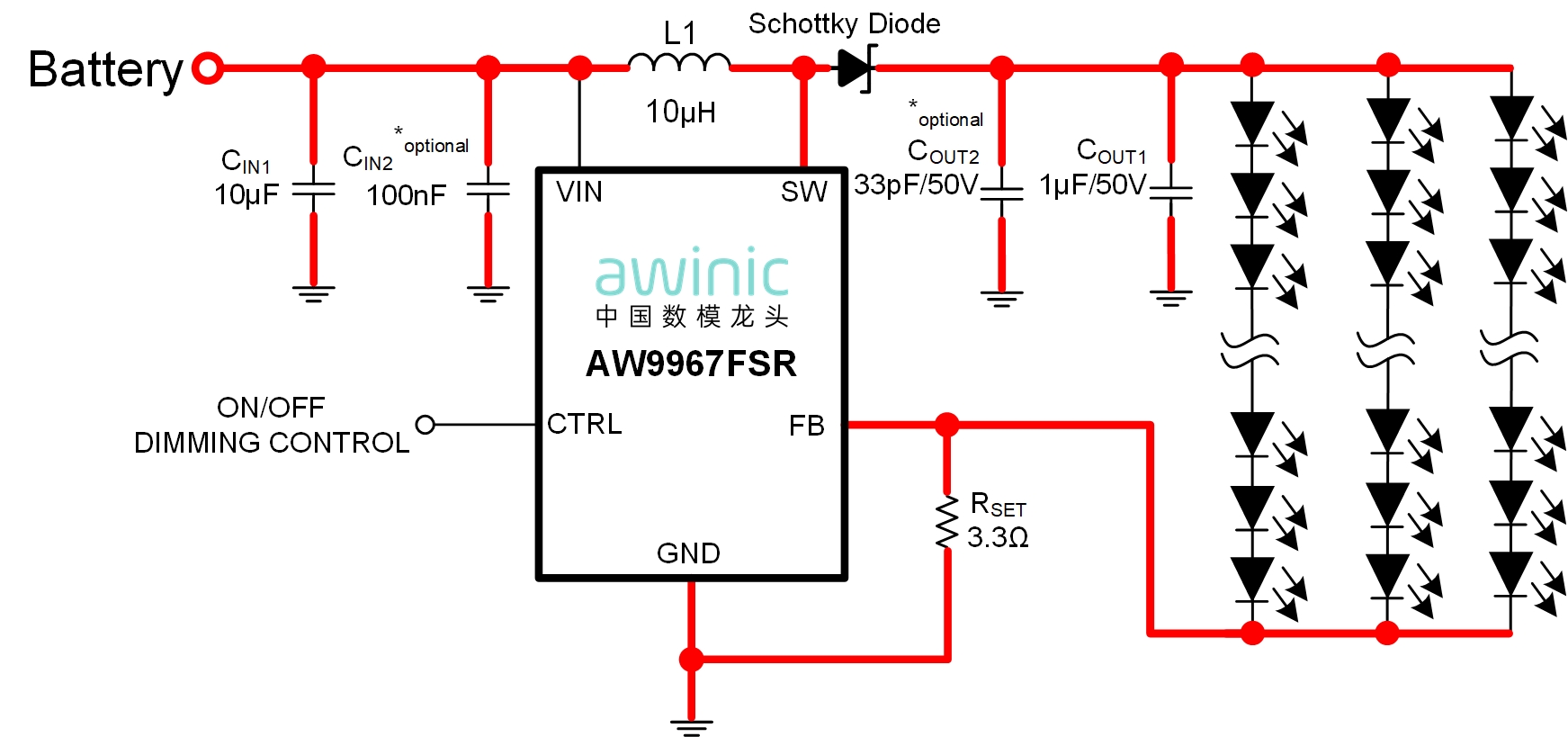

Figure 1: Application with fewer than 50 LEDs

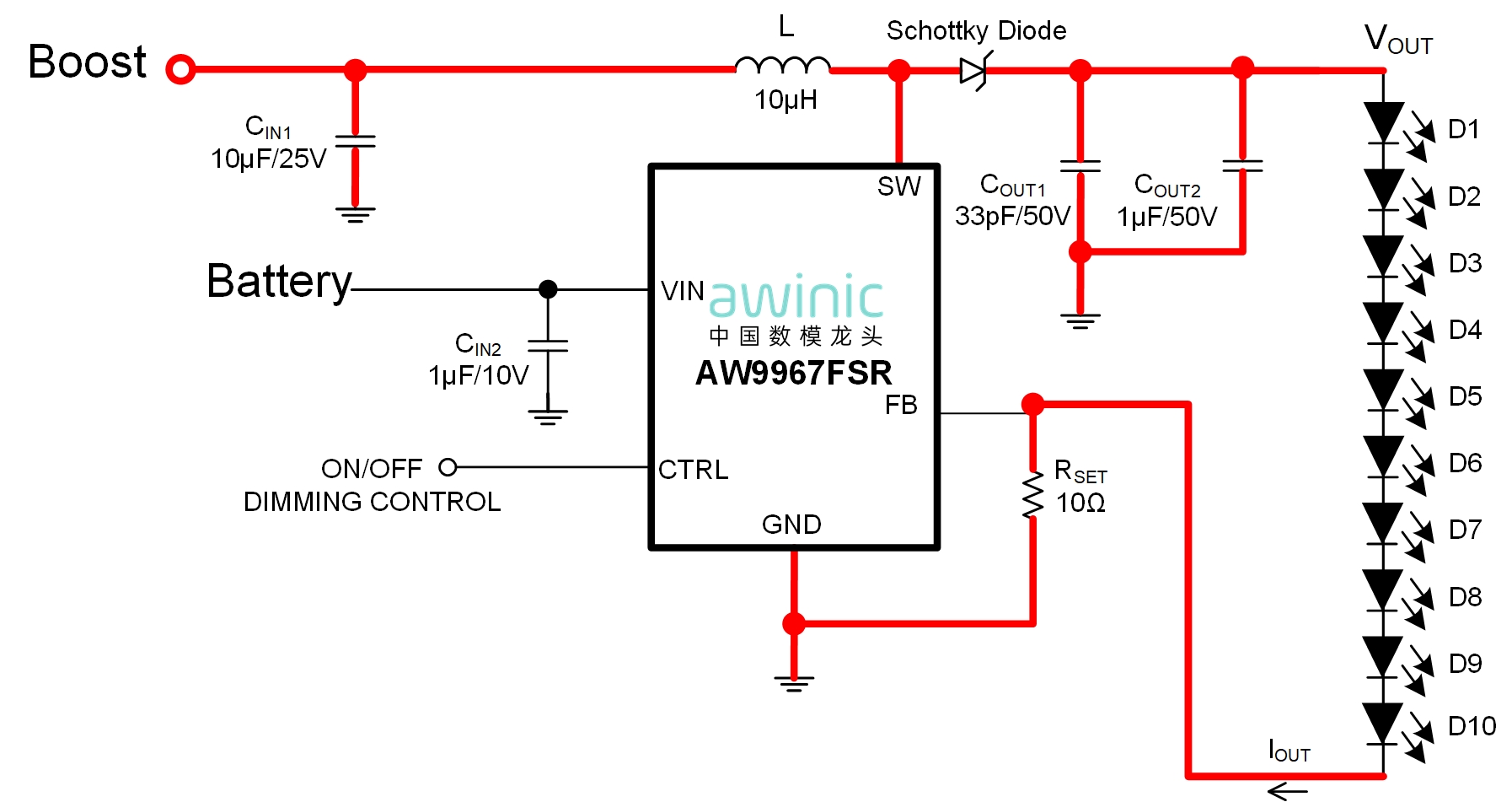

Figure 2: Application with more than 50 LEDs

IPC Network Camera: The "Cool Heart" for 24/7 Operation

IP cameras typically use a 12V power supply and require relatively high LED current, generally greater than 200mA. For this scenario, AWINIC recommends two solutions.

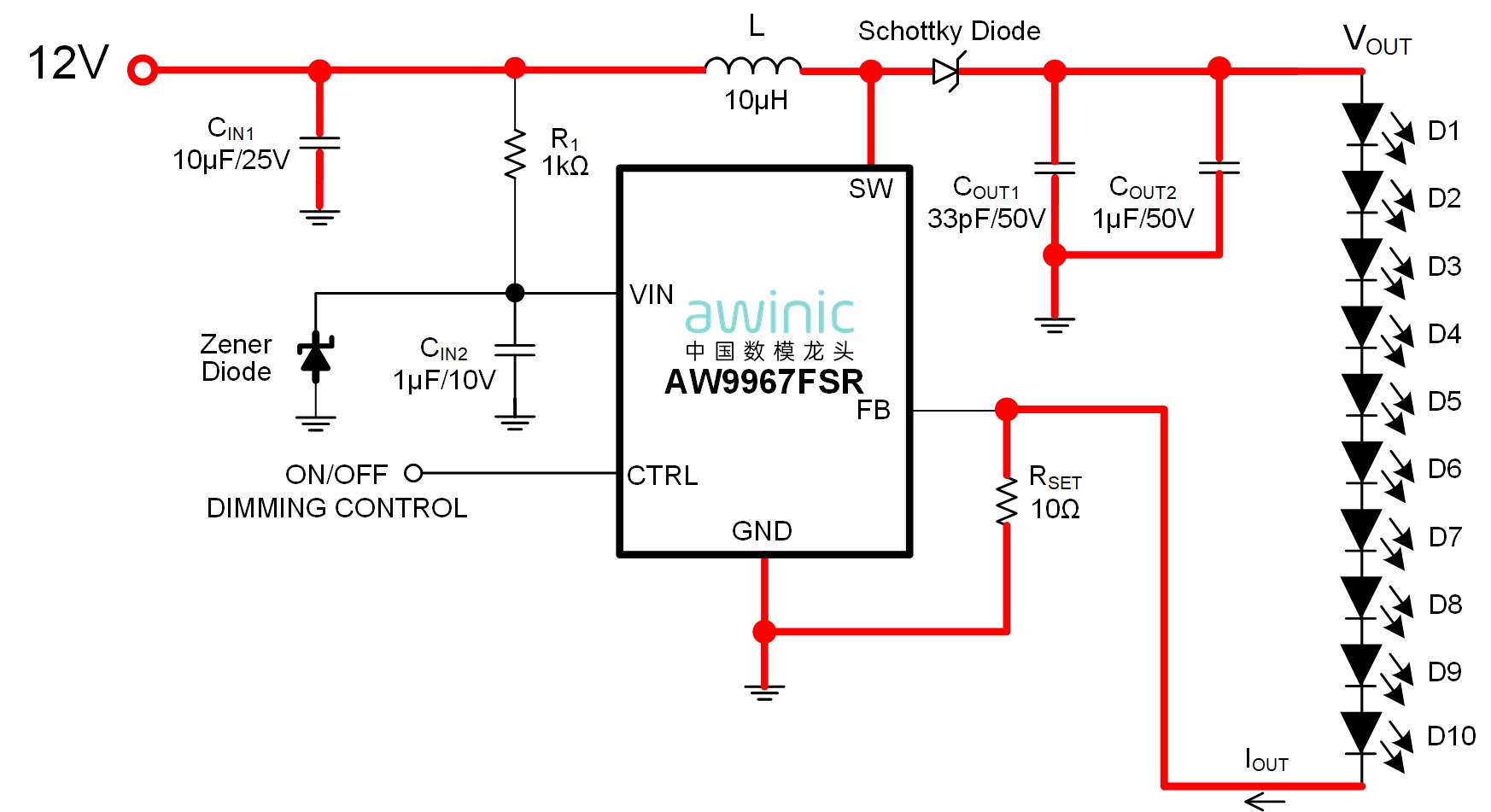

Solution 1: Inductor directly connected to 12V input, with the VIN pin connected to a 5V Zener diode to power the chip.

Requires only one power supply.

However, there is a leakage path from the current-limiting resistor to the Zener diode, resulting in additional power loss.

Figure 3: Solution 1

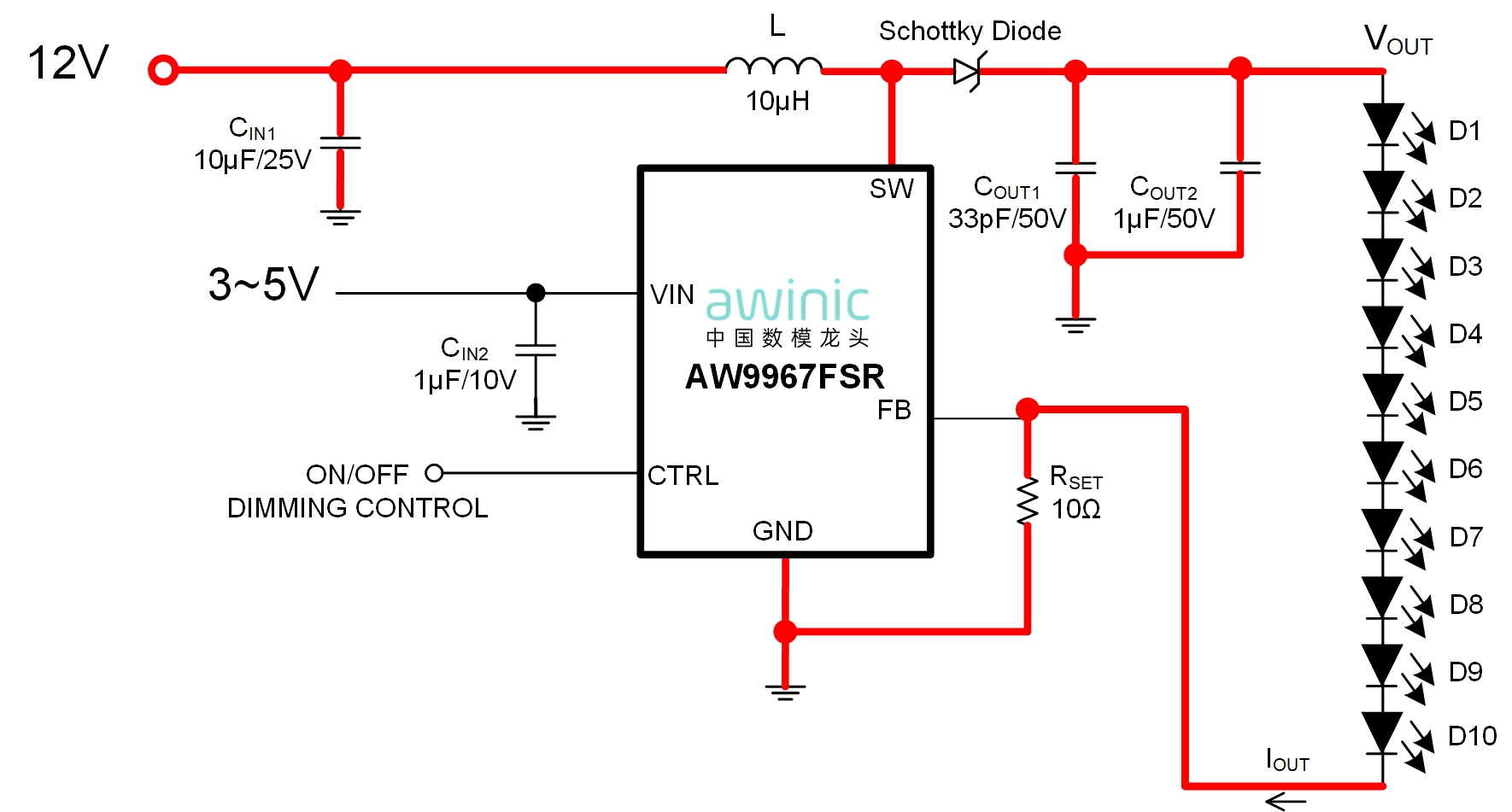

Solution 2: Separate power supplies for the inductor and the chip VIN: 12V for the inductor, and 3~5V for VIN.

Requires an additional low-voltage power supply.

But eliminates the extra power loss.

Figure 4: Solution 2

03 Product Advantages

Figure 5: Significantly Improved Efficiency

Packaging Improvement, Reduced Thermal Resistance

FC (Flip Chip) packaging places the chip upside down, connecting it directly to substrate pads via solder bumps, replacing the wire bonds used in standard WB (Wire Bond) packaging. Compared to WB packaging, FC packaging offers several advantages:

Effectively reduces package thermal resistance, improving chip heat dissipation capability.

Shortens signal delay and reduces internal pin parasitics.

Enables thinner packaging, adapting to more application scenarios.

With the advantage of advanced FC-SOT packaging, the AW9967FSR's thermal resistance (RθJA) is significantly lower by 80°C/W compared to competitors, as shown in the comparison table below.

Table 1: Thermal Resistance Comparison

The AW9967FSR brings more possibilities to the field of backlight driving, thanks to its light-load efficiency far surpassing peers and the low thermal resistance advantage from its advanced packaging.

04 AWINIC Series Backlight Product Selection Table

Table 2: AWINIC Series Backlight Product Selection Table