Driven by the explosive iteration of 5G, Internet of Things, and artificial intelligence technologies, computing power chips are undergoing a dual revolution of performance leap and physical miniaturization. The performance bottlenecks of computing power chips and ultra-thin and light terminals are becoming increasingly prominent. Achieving efficient heat dissipation in a narrow space has become one of the key factors restricting technological progress. When passive heat dissipation architectures (such as vapor chambers/graphene patches/VC) handle high-frequency operations above 3.5GHz, their heat flux carrying capacity has approached the physical limit of materials. The resulting "heat accumulation effect" causes a 40% attenuation in chip performance (data from AnandTech). The user experience gap caused by frequency reduction strategies and device surface temperatures exceeding the human tactile comfort threshold (45℃) – these pain points have also posed unprecedented challenges to thermal management technologies.

Based on the inverse effect of piezoelectric ceramics, Awinic Electronics has successfully developed a new generation of micropump liquid cooling active heat dissipation driver solution. Through high-voltage 180V and medium-high frequency vibration, it drives the cooling medium in microchannels to achieve ultra-low power consumption, ultra-small volume, ultra-high backpressure flow, and ultra-quiet heat dissipation. This efficient active heat dissipation solution greatly meets the heat dissipation needs of consumer electronics and industrial internet devices equipped with high-performance chips or computing power chips, such as mobile phones, PCs, AI glasses, AR/VR headsets, drones, and AI robots.

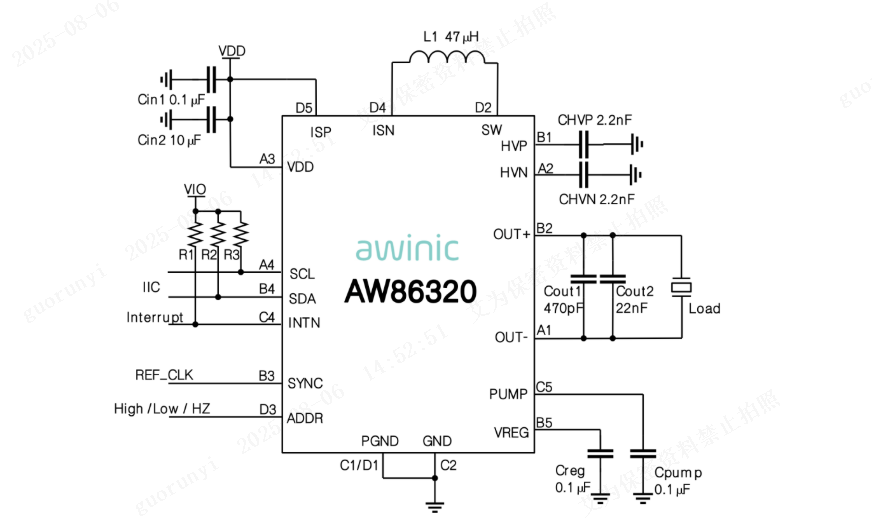

Picture 1 Development History of Heat Dissipation Technology

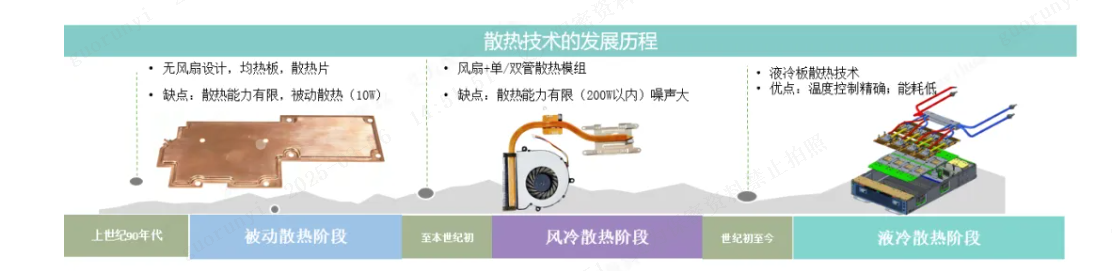

Picture 2 Development History of Mobile Terminal Heat Dissipation Technology

As an active heat dissipation solution, micropump liquid cooling outperforms traditional graphite heat dissipation, heat pipe heat dissipation, and VC vapor chamber heat dissipation in terms of heat exchange coefficient, bending resistance, technical scalability, and high insulation. Micropump liquid cooling heat dissipation technology has the potential to replace and integrate with VC heat pipe heat dissipation, becoming an important technical solution in the field of thermal management.

The micropump liquid cooling heat dissipation system solution consists of three core units: liquid cooling driver chip, piezoelectric micropump, and highly flexible liquid cooling diaphragm.

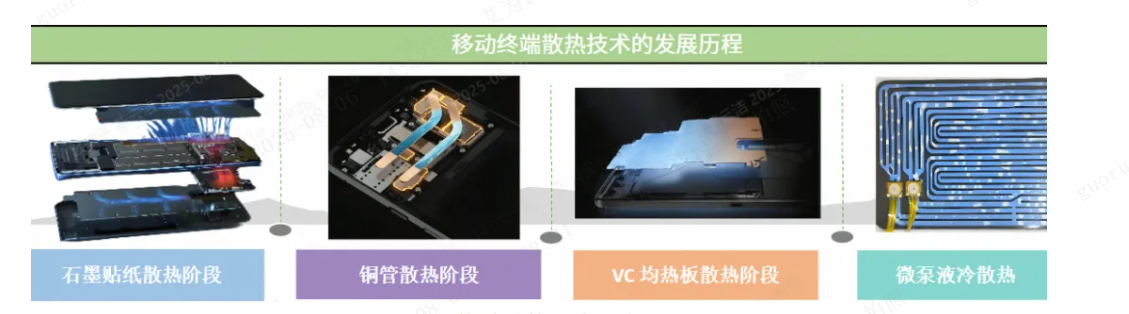

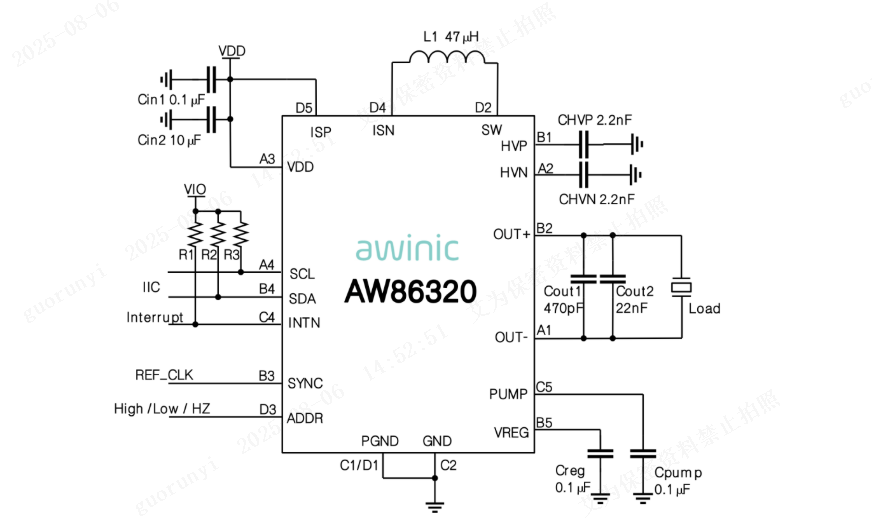

Liquid Cooling Driver Chip

AW86320CSR is a liquid cooling driver chip integrating Boost high-voltage 180V and ultra-low power consumption, providing sufficient energy for the micropump liquid cooling system to generate precise motion required to drive the liquid.

Key Technical Indicators

Wide voltage supply VDD: 2.5~5.5V

Standby current: <6μA

Vout: 180V

THD+N: <1%

Integrated SRAM waveform generator

Supports Auto Dynamic Sine playback

WLCSP 2.2mmx1.8mm-20B Package

Picture 3 Typical Application Diagram

Piezoelectric Micropump & Liquid Cooling Diaphragm

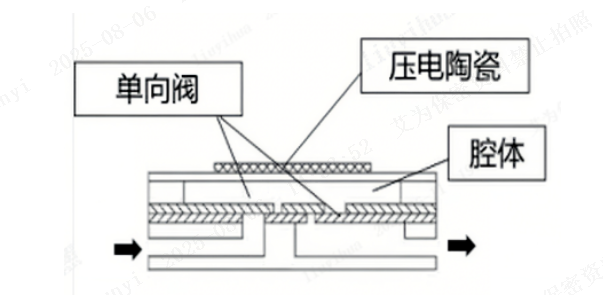

Piezoelectric micropumps utilize the inverse piezoelectric effect of piezoelectric materials, meaning that under the action of an electric field, piezoelectric ceramic materials will undergo tensile/compressive deformation, driving the metal sheet under the ceramic sheet to bulge upward or 凹陷 downward as shown in Picture 4. When the piezoelectric vibrator is under an electric field, the volume of the pump cavity changes, thereby generating "suction" or "pressure" on the liquid, and forming one-way flow of the liquid under the action of a one-way valve. When an alternating electric field is applied to the vibrator, the flow becomes continuous suction and pressure fluid, forming a continuous flow.

Picture 4 Liquid Cooling Pump Load

Picture 5 Micropump Liquid Cooling Diaphragm

Advantages of Liquid Cooling Micropump Heat Dissipation Solution

-

Efficient heat dissipation efficiency

-

Thin and light, bendable

-

Ultra-low power consumption, ultra-quiet

-

Intelligent, high-precision temperature control

Awinic Electronics will continue to deepen its efforts in the heat dissipation field, focusing on the innovation and design development of piezoelectric micropump liquid cooling technology, providing more efficient heat dissipation solutions for high-performance miniaturized devices. It will effectively help terminal products achieve energy conservation and consumption reduction, and continuously inject innovative momentum into the development of the industry.

About Awinic

Leading Chinese Digital-Analog Company

Shanghai Awinic Electronics Technology Co., Ltd. was founded in 2008, focusing on the design of high-performance digital-analog hybrid signals, power management, signal chains, and other ICs. It was successfully listed on the Science and Technology Innovation Board of the Shanghai Stock Exchange in August 2021, with the stock code 688798.

Awinic Electronics has accumulated 42 product subcategories and a total of more than 1,400 product models. The performance and quality of its products have reached the industry-leading level. The company's products are widely used in consumer electronics, industrial internet, and automotive markets, including smartphones, tablet computers, laptops, smart wearables, smart speakers, smart home appliances, mobile payments, the Internet of Things, AI education, smart toys, servers, new energy, robots, drones, security, automotive electronics, and other fields.

In 2024, the company's R&D investment was 510 million yuan, accounting for nearly 17% of its revenue. Technical personnel accounted for more than 74%. It has accumulated 649 domestic and foreign patents, 125 software copyrights, and 595 integrated circuit layout registrations.

Awinic Electronics has been awarded qualifications and honors such as the National Enterprise Technology Center, the Single Champion Enterprise in the audio manufacturing industry, the National Intellectual Property Advantage Enterprise, the "National High-Tech Zone Listed Company Innovation Top 100", the Shanghai Innovative Enterprise Headquarters, the Shanghai Quality Gold Award, the Shanghai Municipal Design Innovation Center, the Shanghai Intelligent Audio Chip Technology Innovation Center, and the Shanghai Hardcore Technology Enterprise TOP 100 list.